High Efficiency Square Bottom Paper Bag Making Machine Automatic

Specifications :

Max. sheet (LxW) | 1200x600mm |

Min. sheet (Lx W) | 540x300mm |

reinforced paper | length 160-410mm |

reinforced paper | width 25-40mm |

Sheet Weight | 128g-250g/m2 |

reinforced paper sheet weight | 180g-230g/m2 |

Bottom Width | 80-180mm |

Bag Width | 180-430mm |

Total Power | 15kw |

Machine Size | 14800x2400x1800mm |

Speed | 50-80bags/min |

Total Weight | 12T |

Glue Type | Water soluble cold glue (hot-melt glue) |

Description :

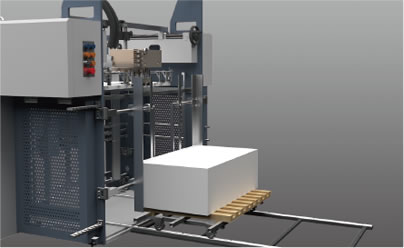

PRY1200CT-430 automatic sheet - feeding paper bag making machine (

Adopt Italy technology ) is suitable for the mass bag production,

it is the first choice of medium and top grade handbag device. The

product adopts mechanical,electricity,light,gas integration

technology, setting a number of its proprietary technology,use

sheet paper as raw material,can one - time finish: paper feeding,

positioning,die - cutting,reinforced paper gluing, reinforced paper

pasting, tube forming, gusset forming, square bottom folding and

gluing automatic, and then compaction output.The variable speed

drive technology, combined with the system of vertical and

horizontal creasing, bottom folding realize trackless bag molding

process, using the PLC programmable control, frequency control

technology to realize the integral multi-dimensional control, more

centralized control and single point remote control operating

system . with characteristics of good quality and high

efficiency,its technology ranks leading level in domestic similar

products.

Suitable paper :

| A | B | C | D | E | F | G |

Max. Size

Min. Size | 1200

540 | 600

300 | 180

80 | 430

180 | 500

250 | 160 410 | 25 40 |

Suitable Paper: Kraft paper, art paper(including film adhesive

paper)

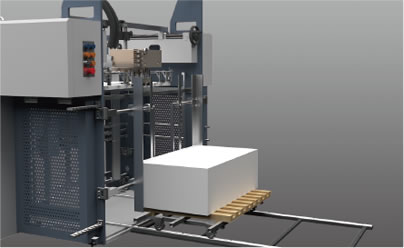

Machine configuration :

1. Feeder: enhanced prestack paper feeder to realize non stop paper

feeding,greatly save the time to load and adjust raw paper.

2. Front and side guides positioning system

3. Hand crank creasing system

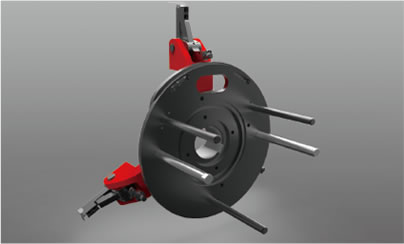

4. Reinforced paper gluing systerm: Print cold glue on Reinforced

paper by glue roller. than paste reinforced paper on paper.

5. Reinforced paper pasting systerm: put one reinforced paper on

the gluing position and compaction.

6. M side making guesst system

7. Big and small edge glue system:Standard configuration big and

small side gluing system,ront and back joint ed both able to

produce.

8. Paper jam checking system

9. Screw rod adjusting bottom clip system:help to shorten the

adjusting time and improve the production efficiency in making

handbags with different specifications.

10. Bottom catch bag roller paper bag fall down alert system

11. Automatic collection system:automatic counting,convenient to

collect bags

Technological process :

Selection and other :

Feeder : enhanced prestack paper feeder to realize non stop paper

feeding,greatly save the time to load and adjust raw paper.

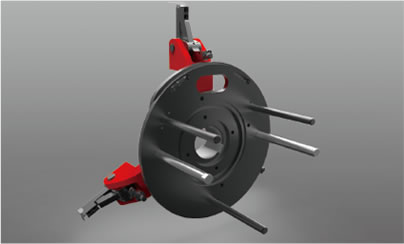

Optional comfiguration Nordson hot melt adhesive system : fast

adhesion product ,quickly enter the next process.

Screw rod adjusting bottom clip system :

help to shorten the adjusting time and improve the production

efficiency in making handbags with different specifications.

Automatic collection system:

Can realize the automatic counting,convenient products collection.

optional confirguration bag compaction table: layers compaction bag

device,fast adhesion,compaction, overlapping output,convenient

collection,improve work efficiency.